8 Simple Techniques For Oems

Wiki Article

All About Mfg

Table of ContentsUnknown Facts About Die CastingThe Ultimate Guide To Lean ProductionThe Definitive Guide to Hon Hai PrecisionNot known Facts About Plastic ManufacturingSee This Report on Manufacturing Industries

The mould closes and the process repeats. Pre-moulded or machined components can be put right into the dental caries while the mould is open, allowing the product injected in the next cycle to create and also solidify around them. This process is known as Insert moulding and enables solitary parts to include multiple materials.

The plastic shot moulding sector has advanced throughout the years from generating combs as well as buttons to producing a vast range of products for many sectors consisting of auto, medical, aerospace, consumer items, toys, pipes, product packaging, and also construction.: 12 Examples of polymers finest suited for the procedure [modify] Most polymers, often described as resins, might be utilized, including all thermoplastics, some thermosets, and some elastomers.

Available materials consist of alloys or blends of formerly developed materials, so item developers can pick the material with the very best collection of residential or commercial properties from a substantial selection. Significant standards for selection of a material are the stamina as well as function required for the final part, along with the cost, however also each product has different parameters for moulding that need to be taken right into account.: 6 Various other factors to consider when selecting a shot moulding material include flexural modulus of elasticity, or the level to which a product can be bent without damage, as well as warm deflection and also water absorption.

Our Hon Hai Precision Statements

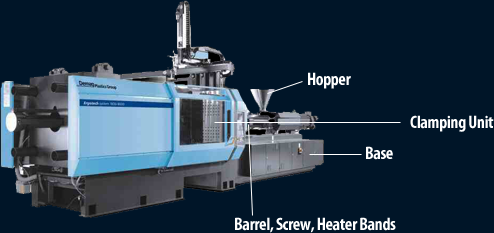

Applications consist of fastenings for securing and also separating outdoor-equipment webbing. Injection moulding devices are composed of a material hopper, an injection ram or screw-type plunger, as well as a heating unit.: 240 Also understood as platens, they hold the moulds in which the parts are formed. Presses are rated by tonnage, which reveals the quantity of clamping force that the maker can apply.

Mould or pass away are the usual terms utilized to define the device made use of to create plastic parts in moulding. Since moulds have actually been costly to manufacture, they were typically just made use of in mass manufacturing where hundreds of components were being produced. Normal moulds are constructed from hardened steel, pre-hardened steel, aluminium, and/or beryllium-copper alloy.: 176 The choice of product to build a mould from is mostly one of business economics; in basic, steel moulds set you back more to build, yet their longer life expectancy offsets the greater first price over a higher number of components made prior to breaking.

Plastic Manufacturing Can Be Fun For Anyone

Injection moulding pass away with side pulls "A" side of need 25% glass-filled acetal with 2 side draws. Close up of detachable insert in "A" side. "B" side of die with side read here pull actuators. Mould design [modify] Basic two plates tooling core as well as tooth cavity are inserts in a mould base "family members mould" of five various parts The mould contains 2 main components, the shot mould (A plate) as well as the ejector mould (B plate).Plastic material goes into the mould through a or entrance in the injection mould; the sprue bushing is to seal firmly versus the nozzle of the injection barrel of the moulding equipment and also to permit liquified plastic to stream from the barrel right into the mould, likewise called the cavity.: 141 The sprue bushing guides the molten plastic to the cavity photos via channels that are machined right into the faces of the An and B plates.

(A) Sprue, (B)&(C)jogger as well as (D)entrances in actual shot moulding product for toys The quantity of resin required to fill up the sprue, runner and also tooth cavities of a mould makes up a "shot". Entraped air in the mould can leave with air vents that are ground right into the parting line of the mould, or around ejector pins and also slides that are a little smaller sized than the holes retaining them.

The air can even end up being so compressed that it fires up and melts the bordering plastic material.: 147 To permit for elimination of the moulded part from the mould, the mould functions must not overhang one an additional in the direction that the mould opens, click here now unless components of the mould are designed to move from in between such overhangs when the mould opens utilizing parts called Lifters.

Top Guidelines Of Manufacturing Industries

The coolant absorbs warm from the mould (which has actually absorbed heat from the hot plastic) as well as keeps the mould at an appropriate temperature level to solidify the plastic at the most efficient rate.: 86 To alleviate upkeep and also venting, tooth cavities and also cores are split right into pieces, called inserts, as well as sub-assemblies, additionally called inserts, obstructs, or chase blocks.A lot more intricate components are formed making use of much more complex moulds. These might have sections called slides, that move right into a tooth cavity perpendicular to the draw direction, to develop overhanging component features. When the mould is opened, the slides are pulled away from the plastic part by making use of stationary "angle pins" on the stationary mould fifty percent. hon hai precision.

The component is then expelled as well as the this website mould shuts. The closing activity of the mould causes the slides to move on along the angle pins.: 268 A mould can generate a number of duplicates of the exact same parts in a solitary "shot". The number of "impacts" in the mould of that part is usually inaccurately described as cavitation.

In many cases, multiple tooth cavity tooling moulds a series of various parts in the same device. Some toolmakers call these moulds family moulds, as all the components are relatede. g., plastic version kits.: 114 Some moulds permit previously molded parts to be returned to permit a new plastic layer to create around the first component.

The 4-Minute Rule for Die Casting

This system can permit manufacturing of one-piece tires as well as wheels. Two-shot or multi-shot moulds are designed to "overmould" within a solitary moulding cycle and also have to be refined on specialised injection moulding devices with two or even more injection units. This process is really a shot moulding process done twice as well as consequently has a much smaller sized margin of error.The second product, a different colour, is injection-moulded right into those rooms - manufacturing. Producers go to excellent lengths to safeguard personalized moulds due to their high standard costs.

Report this wiki page